rubber rollers

We will always support and suggest materials such as rubber, polyurethane and silicone for their unrivaled characteristics that make them ductile and usable in various sectors and different purposes.

Each of these materials according to factors such as temperature, chemical compatibility and the required flexibility, can guarantee better performance than any other, for a specific application.

The rubber offers excellent compressive strength and high tensile strength. It is also resistant to abrasion and has good friction characteristics. Its bonding capabilities with metal surfaces and those of absorbing vibrations are also excellent.

Polyurethane combines the best properties of both plastic and rubber. It provides great resistance to tension and abrasion, excellent values in terms of elasticity and elongation and elastic return., different polyurethane systems have, by nature, good resistance to chemicals, UV and excellent resistance to ozone. Furthermore, these systems have great resistance to most fuels, oils, kerosene and other petroleum-derived chemicals.

Silicone is an extremely light material, resistant to chemical agents, water and saline solutions, resistance to high temperatures and to UV rays. It is also an insulating material and at the same time extremely resistant to impacts.

For these and other characteristics, Rubber, Polyurethane and Silicone are the three materials used to create most of the Technical Items of which many of the objects that surround us are composed.

HD polyethylene, nylon, Teflon and the whole world of those materials commonly called “plastic” are excellent for the production of squeegees, scrapers, gaskets and gears in addition to the coating of rollers themselves; they have excellent chemical resistance, good mechanical rigidity and vibration absorption, some materials are self-lubricating.

What are Technical Items

Technical Items is a generic term that indicates all those objects that can be made of rubber, polyurethane or plastic (such as polyethylene or PTFE) obtained by molding or working with plastic numerical controlled machines.

There are several technical items that vary mainly in size and weight.

Due to their function, these items must have specific characteristics that only rubber, polyurethane, silicone and plastic materials (for example polyethylene) can give: light weight, flexibility and considerable resistance to wear.

Technical Items are used in many sectors from industrial to commercial. However, they can also be used to make consumer components and objects that we use in everyday life.

Sleeves (custom-made rubber tubes), polyurethane doctor blades, special gaskets, anti-vibration mountings, squeegees, rubber strips with special profiles, buffer pads and many other types of products are all components of which many objects that surround us are made up.

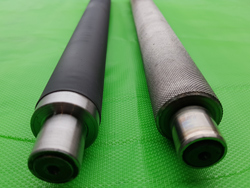

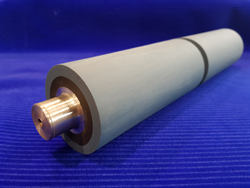

Often they are components that are used in industrial type machinery. In this case, one of the most requested and widespread technical items on the market is definitely the roller. The rollers are widely used, for example, in the bookbinding sector for bending machines (which are used to bend and bind book pages) or in the paper-converting sector.

The rollers are also used for transporting steel, the function for which they are created in polyurethane, and in the leather sector. They are in fact a fundamental element for leather “breaking” machines, machines that are used to cut the skin and bring it into a thinner layer.

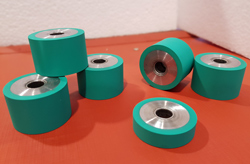

Industrial wheels are also made in medium-sized or large-sized polyurethane, for heavy-duty applications such as the transport of heavy loads.

For example, we are talking about wheels for forklifts, for wire-guided systems, for AGV systems or for automatic storage systems; wheels for industrial plants for wood or glass processing or in the mining sector and for many other applications.

Not only large machines, even small wheels can be manufactured, for different non-industrial users, for example, they are supplied for counting notes machines.

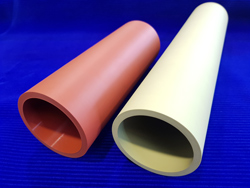

Another important technical item is the sleeve. Tailored to the needs, it is a fundamental element in the printing sector, but also in the food industry, for engines and for many other products.

Tailor-made technical items

The technical items are tailored made using an industrial 3D molding machine, which creates an initial model with the characteristics required by the customer. With the help of a numeric controlled machine, a series of pieces identical to the model are obtained and a perfect product in all its parts.

Thanks to the mechanical workshop of which we dispose of and to the know-how gained over the years, it is possible to make the molds necessary to produce each component very quickly.

Before starting the actual production and proceeding to the expensive construction of the mold, we can realize a prototype on which to study then the possible modifications starting from the technical drawing supplied by the customer.

For information and quotes click here